Among the key steps, bluing is the one that gives the hands their unique blue color. The process is complex and involves heating the hands to around 290-300°C. Known as thermal oxidation, this process creates a thin layer of iron oxide on the surface of the hands, which gives them a deep blue hue. Controlling the temperature is crucial: too hot or not hot enough, and the color may vary.

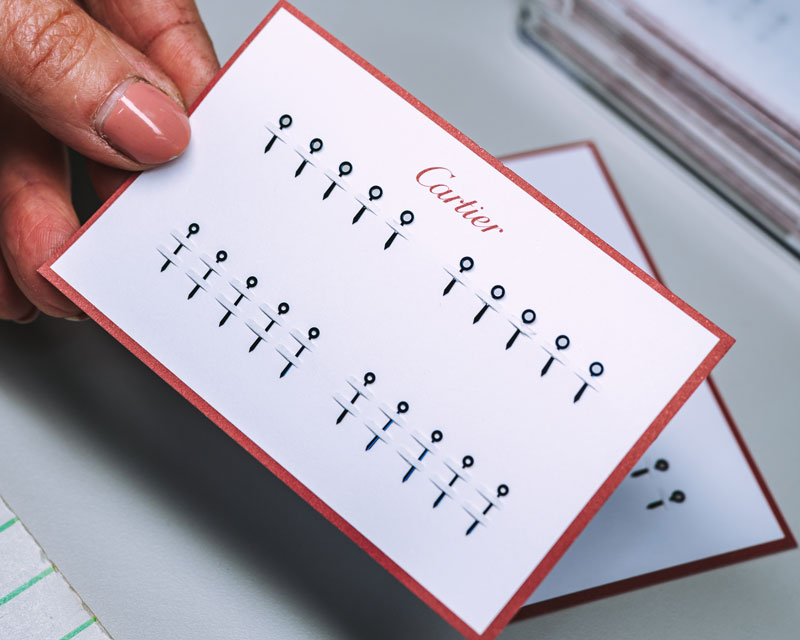

The finished hands are then carded, meaning they are carefully placed in specific holders to prevent scratches and deformations. Finally, they are stored under controlled conditions until they are ready to be assembled onto the watches.

Cartier's know-how: the production of watch hands

In La Chaux-de-Fonds, Cartier's watch manufacture has a specialized workshop dedicated to the production of watch hands. The production process requires great precision and involves several essential steps.

Each step is crucial to ensure the quality and aesthetics of the watches: cutting and shaping, initial polishing, drilling the fixing hole, bluing, final polishing, quality control, packaging, and storage.

Mineral Glass

The mineral glass workshop at the manufacture is distinguished by its expertise in creating watch crystals with complex shapes, which give Cartier models their unique aesthetic.

Unlike sapphire crystal, known for its hardness and scratch resistance, mineral glass is more fragile but offers superior shaping and deforming possibilities. This material is ideal for Cartier's typical shaped watches, such as the Crash, Tortue, or Tank Américaine, where the curve and bend of the glass are essential elements of the design.

Overview of the manufacturing process

Chevage is a hot deformation process. It involves heating the glass to a precise temperature, allowing the craftsman to bend it and give it the desired curvature. Controlling the temperature and heating time is crucial, as overheating or cooling too quickly could damage the glass or alter its shape.

Anglage involves beveling the sharp edges of the glass on all four sides. This is an essential step, not only to provide a refined finish to the glass but also to ensure the watch's water resistance. Indeed, a perfectly fitted glass is essential to prevent water and dust from entering the watch case.

The artisan's eye is fundamental here. Artisans must have great expertise and solid experience to handle mineral glass with the precision required by Cartier's standards.