Why is Magic Gold so magical?

Magic Gold was developed by Hublot in collaboration with EPFL (École Polytechnique Fédérale de Lausanne). The goal was to create an 18-carat gold that is virtually scratch-resistant, combining the prestige of gold with the extreme durability of high-tech materials.

To achieve this, Hublot fused pure gold with a boron carbide-based composite — one of the hardest materials in the world, commonly used in military armor.

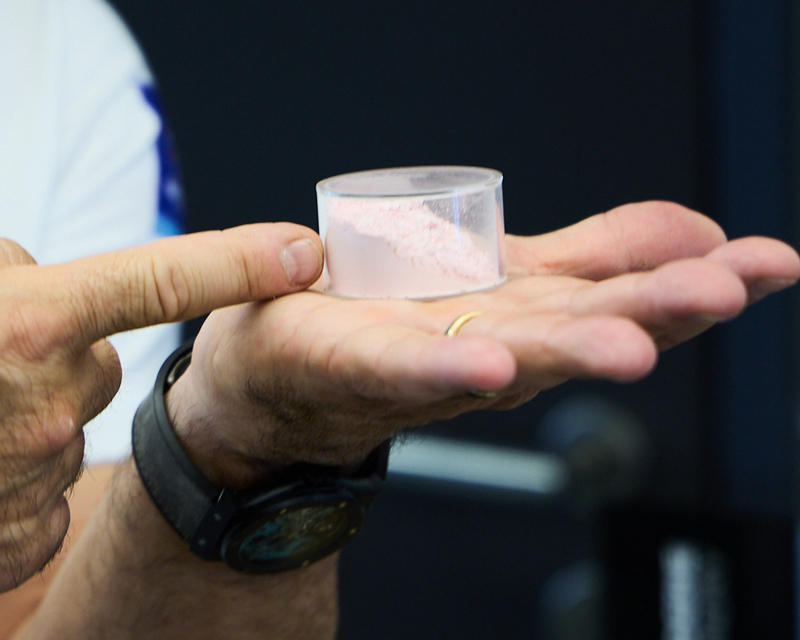

The process begins with the creation of a mold made from porous ceramic, into which the boron carbide is compacted and sintered to form a rigid, perforated structure. This structure is then infiltrated under high pressure with 24-carat liquid gold, filling the micro-cavities of the material.

The result is a certified 18-carat hybrid gold with a hardness of approximately 1000 Vickers—compared to just 400 for traditional gold. This patented process gives rise to a metal that is noble, innovative, and nearly indestructible.